project23:Performance

Contents |

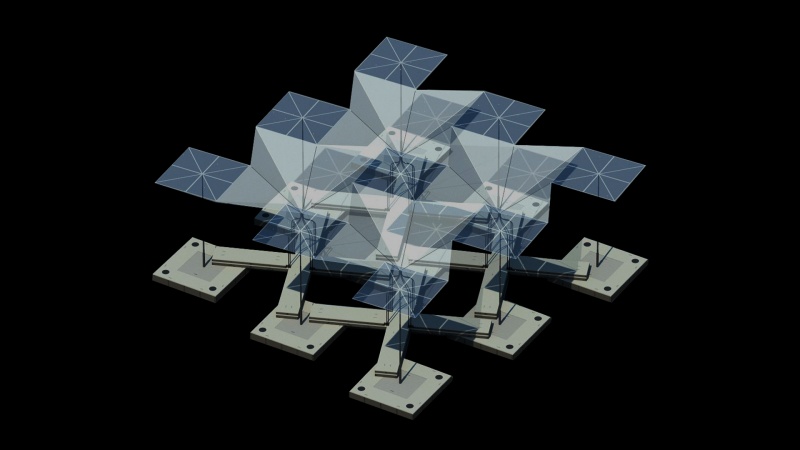

Self-Constructing Architecture

If automated, the Deployable Bridge can represent a type of architecture which effectively builds itself.

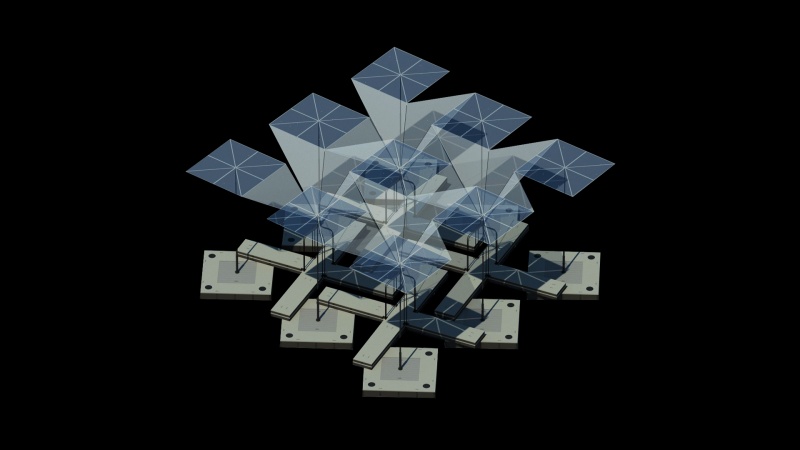

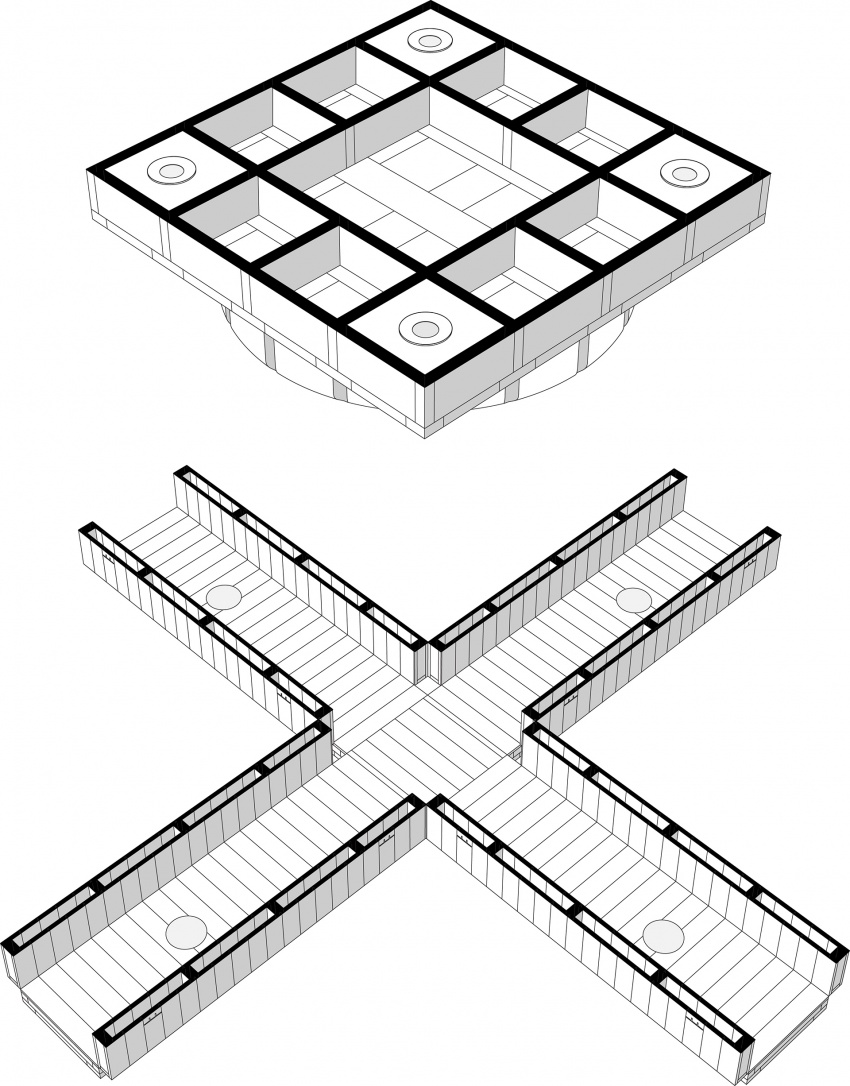

Two-Unit System: ◘ & ✚

One distinct feature of the performance of the Deployable Bridge is its ability to act as simple linkage of two basic units (◘ and ✚). The units are connected and disconnect by a simple lightweight yet strong hinge around which both platforms (◘) and paths (✚) can rotate freely. This minimal model acts as a universal framework which supports a wide range of scenarios and reacts flexibly for disparate functions.

Base Geometry

As a simple linkage of two basic units (SQUARE and CROSS), the base geometry was designed as a universal framework to support numerous configurations. A single platform unit (SQUARE) comprises only 16 m2. However, when single platform units (SQUARE) are combined with path units (CROSS) in a cluster or large field, a more buoyant, stable floating system emerges which can support greater weights and more complex functions.

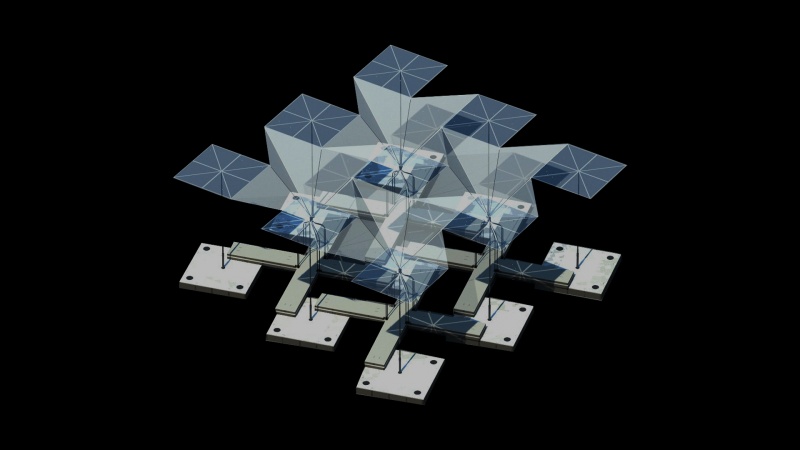

Functional Constraints

The base was styled according to the constraints of several primary functions: bridge, chill-out spot, public platform, pontoon, water taxi, and storage container. When deployed, the base functions optimally as a bridging mechanism for collective transit; when closed, the base establishes a cohesive surface which maximizes usable surface area on water. Volumes which provide seating in the closed state open to provide railings in the deployed state. Smart units alone can act as water taxis for individual transportation.

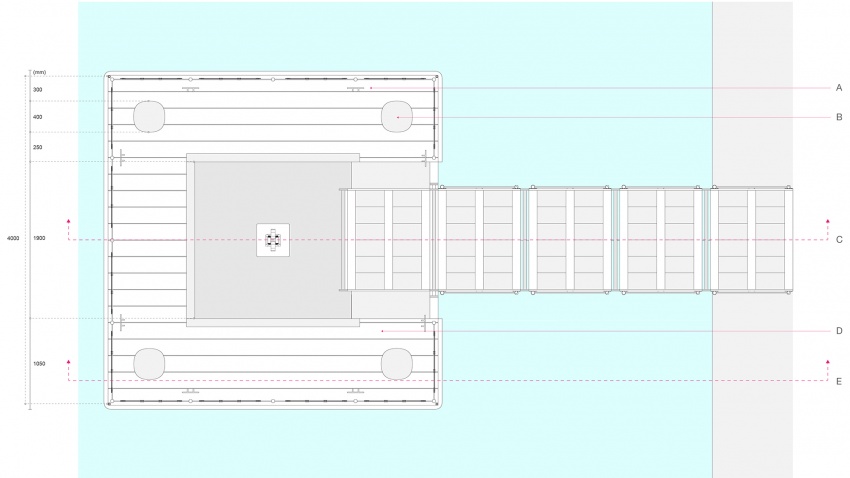

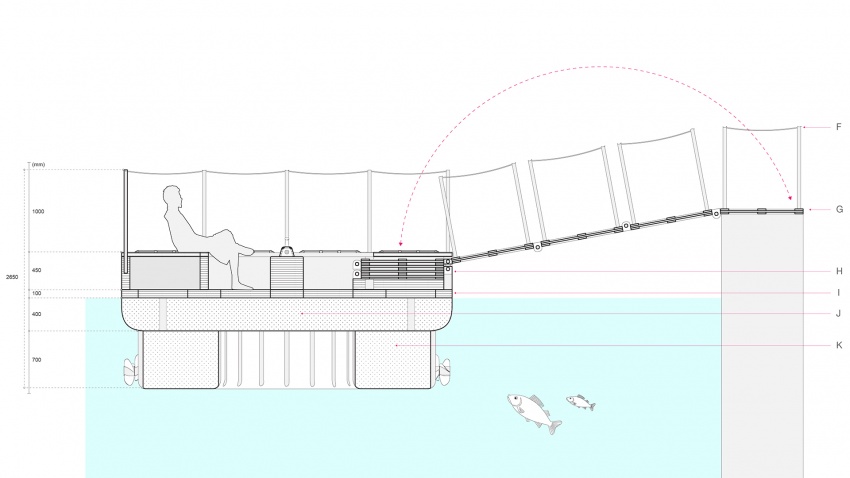

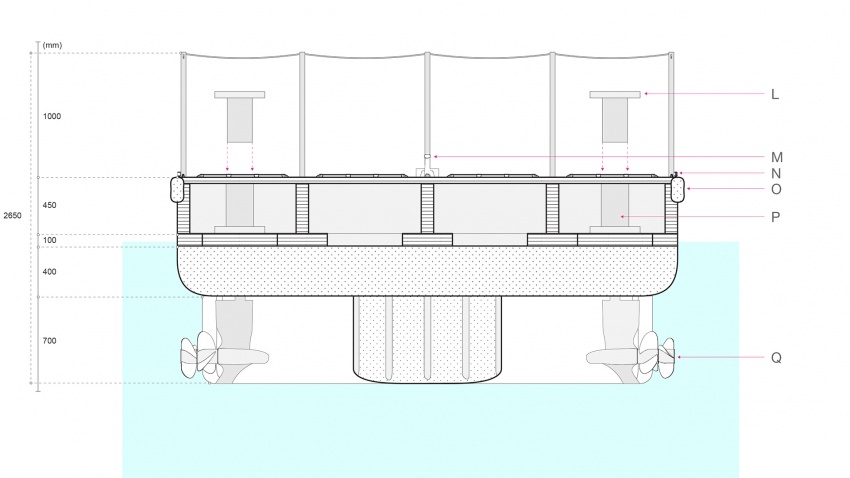

Smart Unit: Plan + Sections

KEY:

A. Galvanized Iron Cleat bolted into steel angle on frame

B. 400 mm diameter removable hinge connector, steel core with Polyethylene coating

C. Section Cut 01

D. 200 mm removable pressure-treated wood decking

E. Section Cut 02

F. 1 m removable aluminum safety railing

G. 4 m deployable gangway with 200 mm wood decking

H. Galvanized steel hinges with bolted connectors for deployable gangway

I. 100 mm pressure-treated wood frame, 1.5 m freeboard

J. High-density molecular weight Polyethylene HD-PE Lupolen

K. Polyethylene HD-PE Lupolen, buoyancy capacity of 376 kg/m2

L. 400 mm diameter removable hinge connector, steel core with Polyethylene coating

M. Manual engine controller, connected to GPS sensors

N. Red/Green navigation lights

O. Vinyl dock fender/bumper

P. 420 mm diameter Polyethylene tube (receives hinge connector)

Q. Volvo Penta DPS drive motor (directional thruster)

Logistics

As a system available for public use, the Deployable Bridge would ideally be automated and operated from a remote location. The operator could assign routes for specific functions and times by selecting from a list of pre-determined standard formations useful for common scenarios. These formations would comprise optimal spatial arrangements and degrees of deployment to suit select functions. Uncontrollable changes in the environment would trigger certain responses from the system. For example, an incoming ship would cause the deployed bridge formation to recede temporarily to allow the ship to pass. Smart units would be equipped with GPS to detect their position on-site and receive instruction signals from the operator.

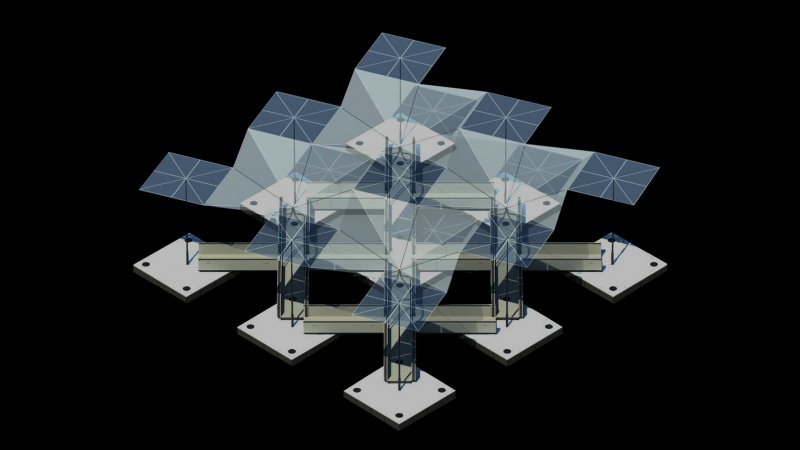

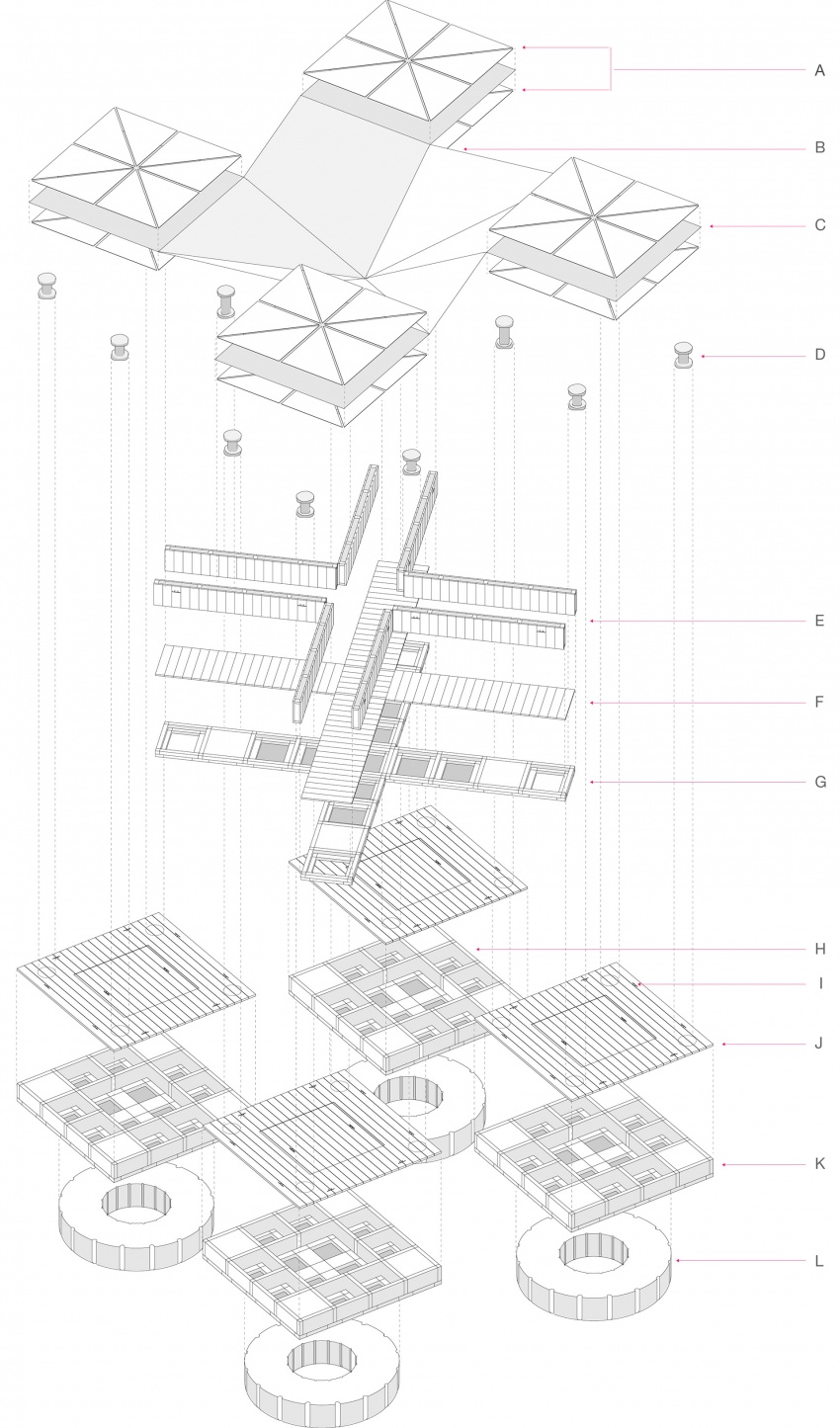

Smart Unit: Exploded Axonometric

KEY:

A. Interchangeable rigid canopy panels with solar panel option

B. Lightweight translucent canopy skin with elastic framework / pistons

C. Adjoining membrane sandwiched by rigid canopy panels

D. 400 mm diameter removable hinge connector, steel core with Polyethylene coating

E. 1 m tall wood frame railing, doubles as seating when not deployed

F. 200 mm removable pressure-treated wood decking for pathways

G. 250 mm tall 100 mm pressure-treated wood panel frame

H. 550 mm tall storage space containers for canopy members

I. Galvanized Iron Cleat bolted into steel angle on frame

J. 200 mm removable pressure-treated wood decking for platforms

K. 550 mm tall 100 mm pressure-treated wood panel frame

L. 700 mm tall Polyethylene HD-PE Lupolen, buoyancy capacity of 376 kg/m2

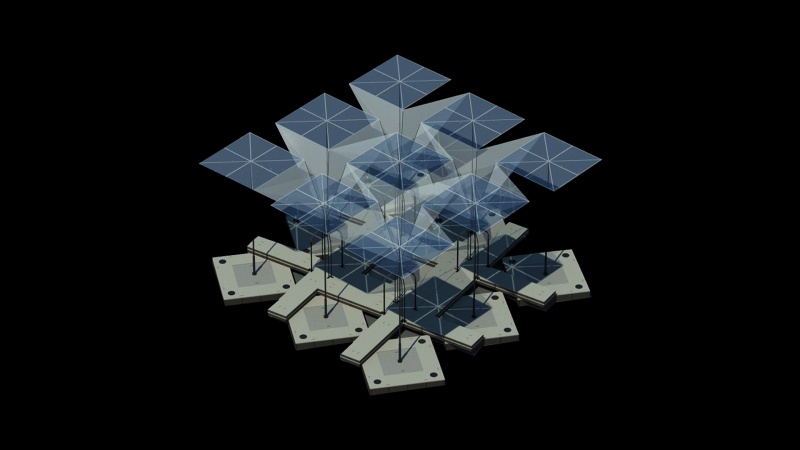

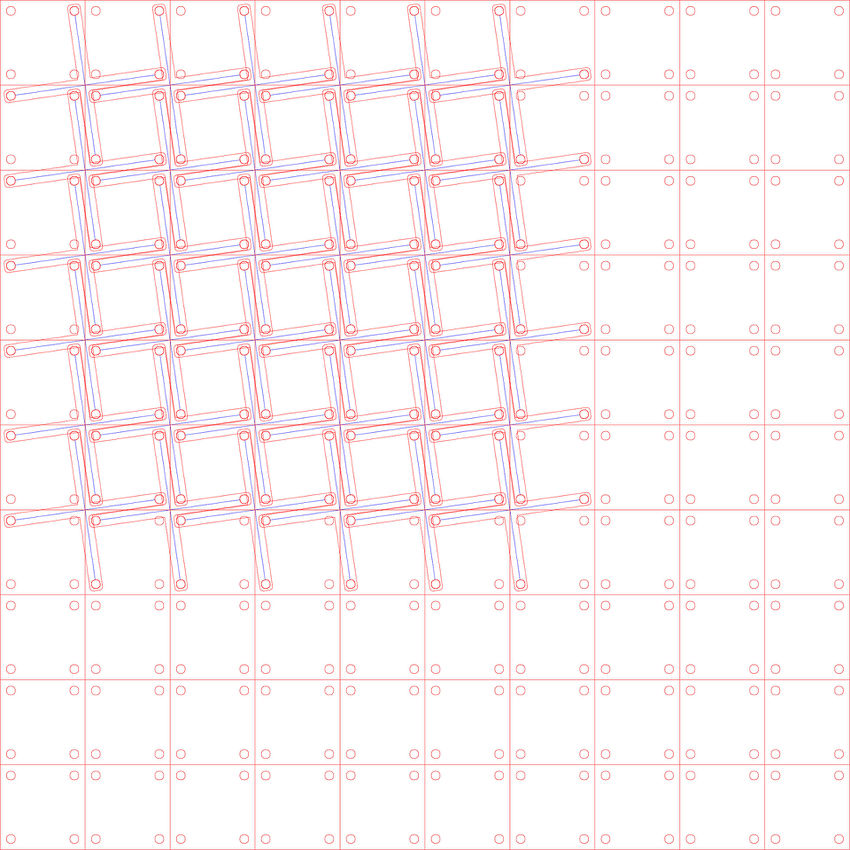

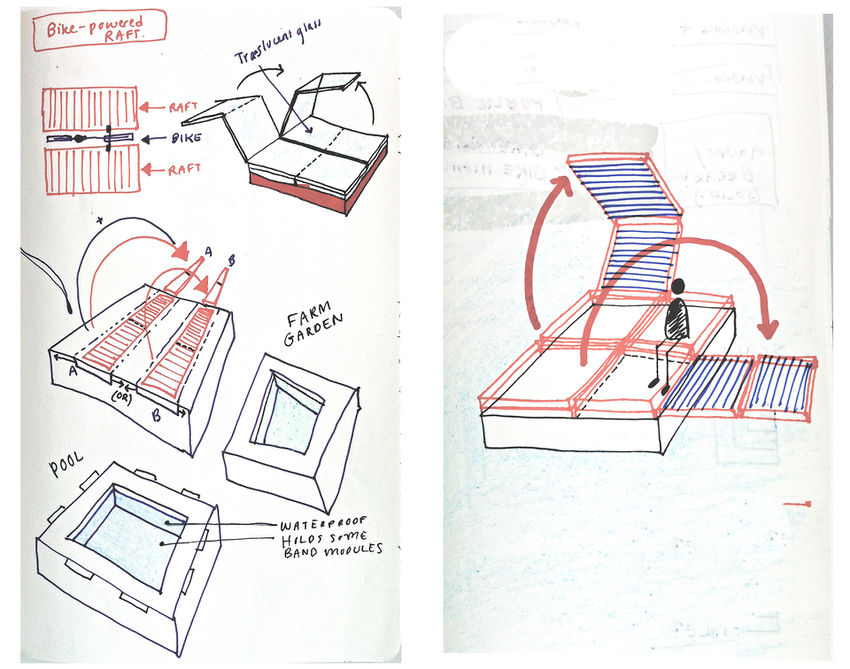

Base Geometry Sketch

This preliminary sketch established a framework for the base geometry of the Deployable Bridge. The Grasshopper plug-in for Rhinoceros was used to determine the optimal configuration for deployment. Variables in the study included (1) the position of the rotation axis on platforms (◘), (2) the position of the rotation axis on the pathways (✚), (3) the width of the platforms (◘), and (4) the width of the pathways (✚).

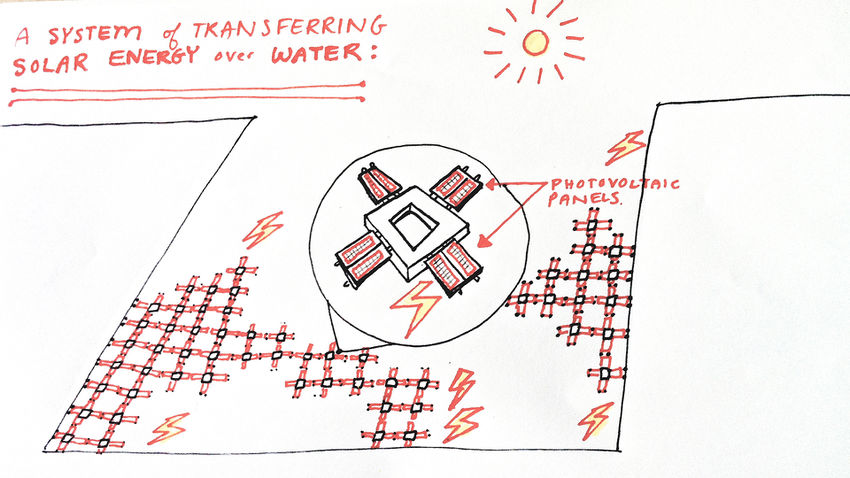

Sketches of Alternative Functions

The deployable bridge aims to support the programs of recreation, relaxation, sustenance, and transit. For example, an RDM student may sit on a cluster of platforms in their non-deployed formation with the optional canopy in place. This would offer a dry, sheltered place to chill during lunch break. Another more permanent cluster of platforms may support a floating farm. A bridge configuration may transport people to all the other projects on-site and any points along the shoreline, with the aim of bridging marine life with shore life. This includes connecting sailors, students, workers, and local residents. Concurrently, another formation may provide a stable floating pontoon for boat repair.

A canopy version equipped with solar panels to collect energy could be multiplied to comprise a floating solar farm with maximized surface area. The angle of the surfaces of the canopy could be adjusted for optimal sun exposure, and energy could be transferred from platform-to-platform into the smart units, which could serve as floating batteries. Optimally, this configuration could extract excess energy generated by certain projects on-site and distribute this energy to projects in need.