project34:Performance

The structural morphology of the project is derived from diatoms, a major group of algae. They exist as unicellular organisms, but often form colonies. The global and local articulation of their unique cell wall made of silica (hydrated silicon dioxide) is the main point of reference here.

Global Geometry

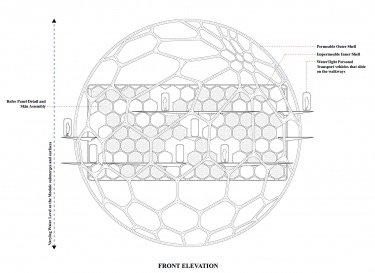

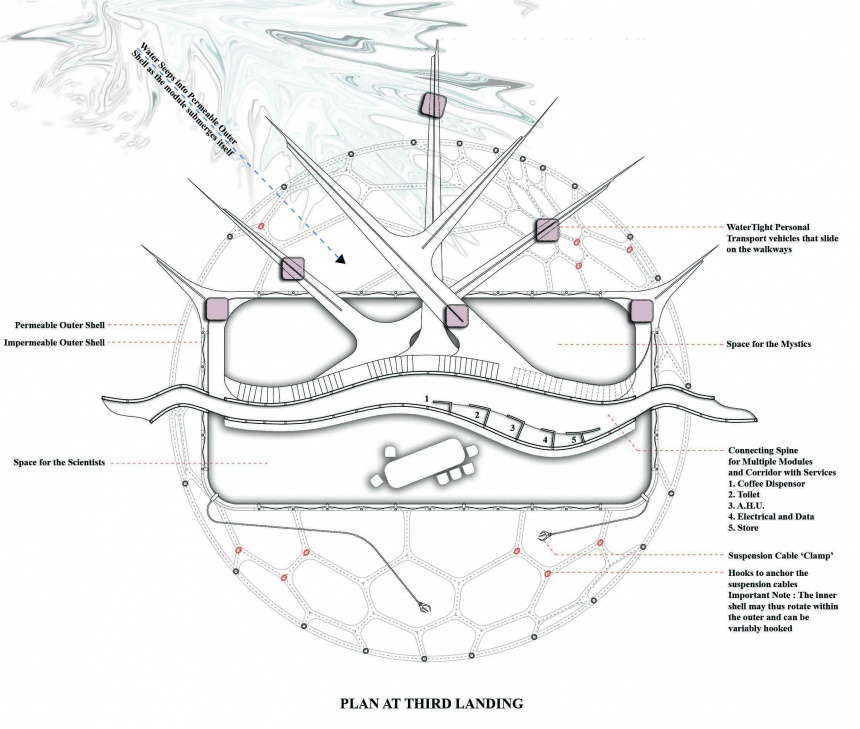

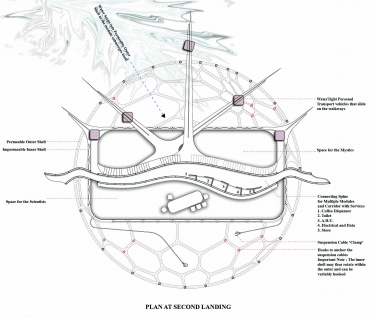

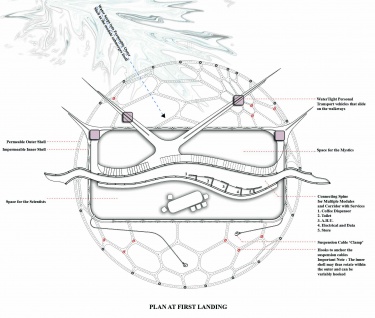

Diatom frustules are often dome-like or rounded at the edges to form structures of minimal weight and material usage that handle compression loads of fluid pressure and point-compression loads of predators efficiently. Individual cells connect to form colonies with 'wrench-shaped, overlapping, interlocking spines' that can slide over each other to form linear and curvilinear global configurations. In the design, an outer permeable spherical shell and inner (‘streamlined’) filleted cuboidal shell was arrived at.

Local Geometry

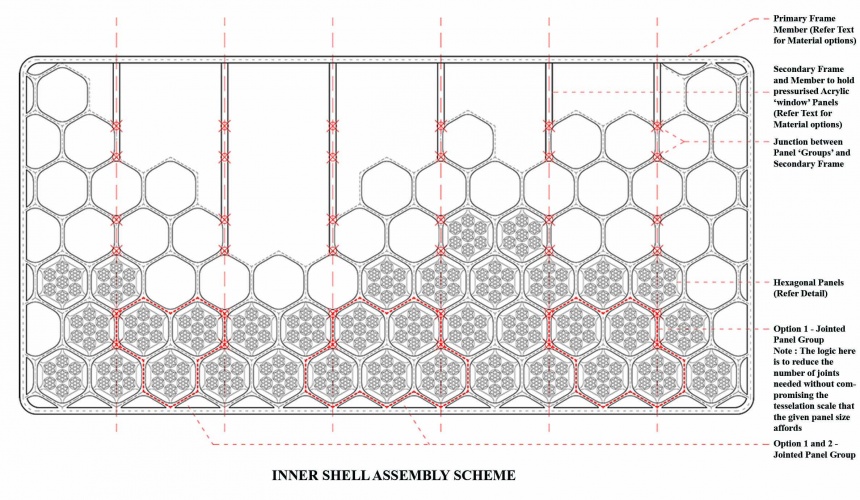

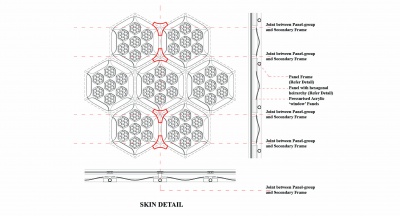

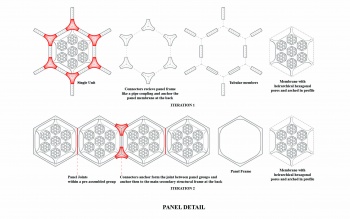

Inspite of being constituted of an extremely brittle material, silica, because of their formal articulation these cell walls exhibit exceptional mechanical strength. Each 'panel' in the frustule has a complex hierarchical organization of layers with varying pore sizes. The central layer is often hexagonal, given the high compression resistance with minimal weight of honeycomb like structures.

Material and Weight of the Water Crafts

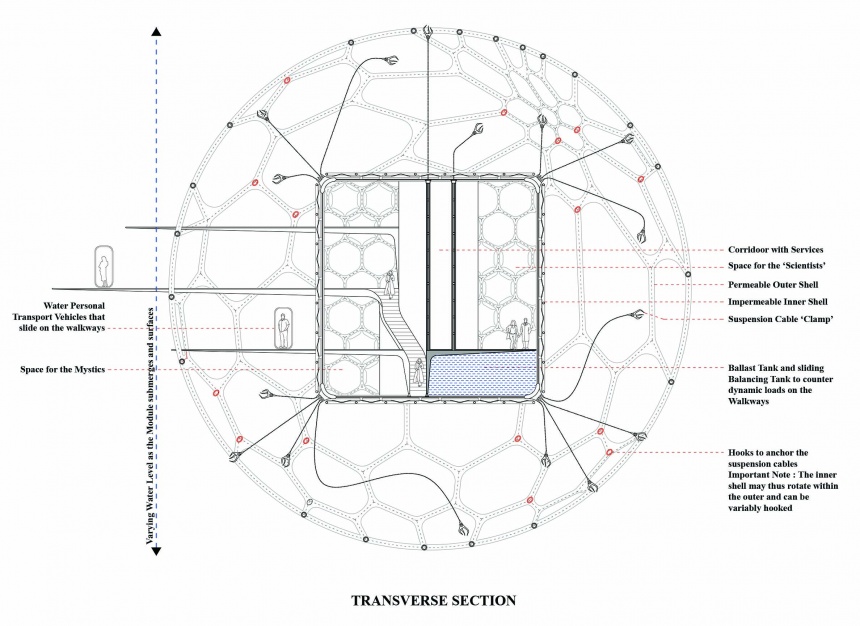

Since, the modules need to be able to submerge and surface in the water, the choice of material between steel alloys of titanium and aluminum, against (lightweight) carbon fibre will depend on how much the building needs to weigh. For an impermeable volume of 3800 cubic meters, a ballast tank of 350 cubic meters is provided. Alternatively, a heavy material like lead placed at the bottom of the shell may be also be additionally employed for the balancing/submerging actions.

The Ballast tank area is located below the scientist’s section and also consists of a ‘mobile’ balancing tank that may slide to counter the dynamic loads on the walkways in the mystic’s section of the module.

However, in the future, a component system of a 'compressive' material like glass reinforced concerete may be apt. It may also help minimize problems that metals pose in underwater constructions. Research is being conducted on such bio-materials.

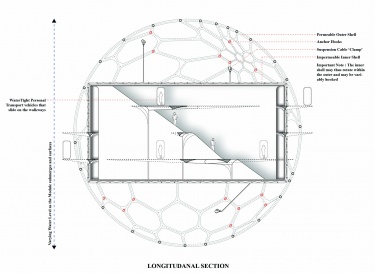

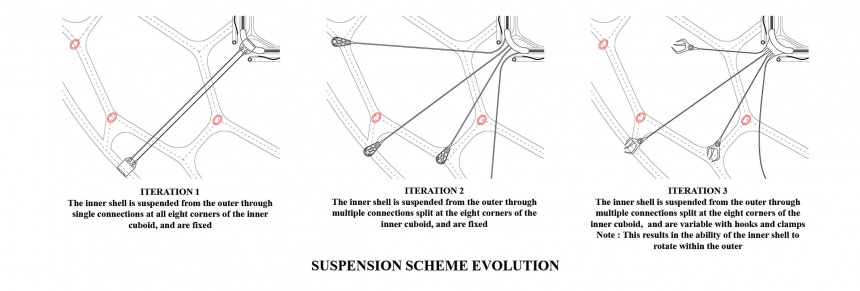

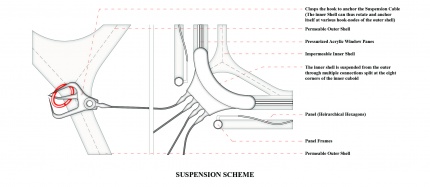

Structure

The inner shell is suspended from the outer with the means of cables. These cable split at the eight vertexes of the inner shell, distributing the weight evenly on the outer. The outer shell parameterizes its node-hooks with attractor points at places of greater load. Clamps at the ends of the cables can anchor themselves variable to different hook-nodes of the outer shell, affording a possibility of rotation for the inner shell.

The interior walls are suspended in a similar fashion from the outer shell with cables.

The walkways branch out (with the help of brackets) from the interior walls but rest on the outer and inner shells.

Assembly and Sizes

The inner shell consists of a primary frame (metallic member) that runs along the edges of the cuboid. Members that span the primary frame form the secondary frame and support pressurized acrylic ‘window’ panels. The hexagonal panel group is then anchored to the secondary frame. The acrylic panels don not follow the hexagonal tessellations and are much larger in span to minimize problems of joint sealing against water seepage. The individual panels are pre-assembled as panel groups that are then connected at specific nodes to the secondary frame. The logic here is to reduce the number of joints needed without compromising the tessellation scale that the given panel size affords.

Dimensions of the inner shell – Height – 12.5m, Width – 12m, Length – 25m

Dimensions of the outer shell – Diameter – 28m

Dimensions of the Hexagonal Panels – Inscribed within a Bounding Box of Height-2.15m, Width-1.85m