project16:Performance

(→FABRICATION) |

|||

| Line 30: | Line 30: | ||

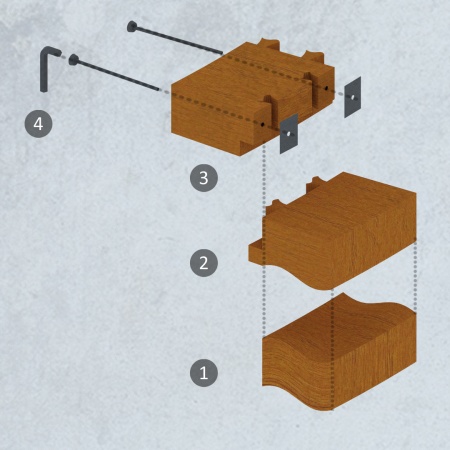

'''Exploded view of the structure: Assembley''' | '''Exploded view of the structure: Assembley''' | ||

| − | 1. Stacked joint: the geometry of the block increases the friction between the blocks. The [http://en.wikipedia.org/wiki/ | + | 1. Stacked joint: the geometry of the block increases the friction between the blocks. The [http://en.wikipedia.org/wiki/Ruled_surface ruled surfaces ] is a result of the [http://www.robarch2012.org/workshops#RotterdamI robotic wire cutting] |

2. Puzzel join: the joint both defines the structure and is resists bending moment. The geometry of the the block's is a result of the [http://www.robarch2012.org/workshops#StuttgartI robotic milling] | 2. Puzzel join: the joint both defines the structure and is resists bending moment. The geometry of the the block's is a result of the [http://www.robarch2012.org/workshops#StuttgartI robotic milling] | ||

| Line 99: | Line 99: | ||

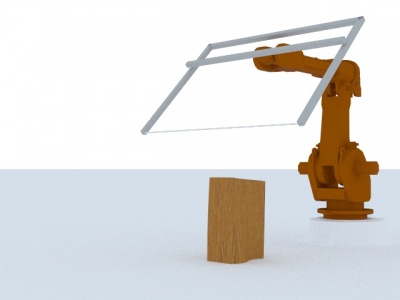

Two robotic fabrication methods are used to give the massive wooden blocks their unique shape. | Two robotic fabrication methods are used to give the massive wooden blocks their unique shape. | ||

| − | The first method is wire cutting, where a diamond wire suspended in a frame which is mounted on the 6 axis robot is used to cut the wooden blocks into geometries based ruled surfaces. | + | The first method is wire cutting, where a diamond wire suspended in a frame which is mounted on the 6 axis robot is used to cut the wooden blocks into geometries based [http://en.wikipedia.org/wiki/Ruled_surface ruled surfaces]. |

Similar method has been implemented for cutting stone and foam using hot wire instead of diamond wire. An example of this fabrication method is the [http://www.youtube.com/watch?feature=player_embedded&v=BEjbjzw3Ha4MSc2 Hyperbody 1:1 prototypes]. Regardless of material the method is an effeicent way of producing unique elements that are based on ruled geometry. | Similar method has been implemented for cutting stone and foam using hot wire instead of diamond wire. An example of this fabrication method is the [http://www.youtube.com/watch?feature=player_embedded&v=BEjbjzw3Ha4MSc2 Hyperbody 1:1 prototypes]. Regardless of material the method is an effeicent way of producing unique elements that are based on ruled geometry. | ||

Revision as of 06:50, 19 January 2013

Performance

STRUCTURE & Assembley

Exploded view of the structure: Assembley

1. Stacked joint: the geometry of the block increases the friction between the blocks. The ruled surfaces is a result of the robotic wire cutting

2. Puzzel join: the joint both defines the structure and is resists bending moment. The geometry of the the block's is a result of the robotic milling

3. Steel plates 3 mm

4. Each block is post stressed after assembly to avoid material failure, since the join relies on wood's strength.

Exploded view of the main building (right)

1. Structural wooden blocks

2. Spacial wooden block

3. Glazing

4. Steel tensile structure carrying the roof glazing.

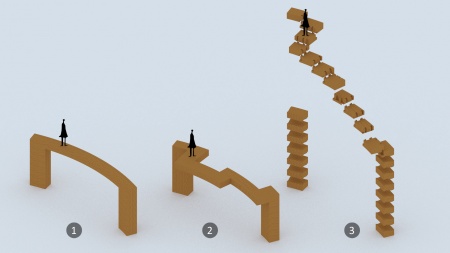

Structural Principal

1. Basic Structural Principle: wooden beam resting on wooden pillars.

2. The load bearing elements are shifted according to the desired styling

3. The puzzle join defined the shifted geometry, The join relies on the material strength of the massive wood.

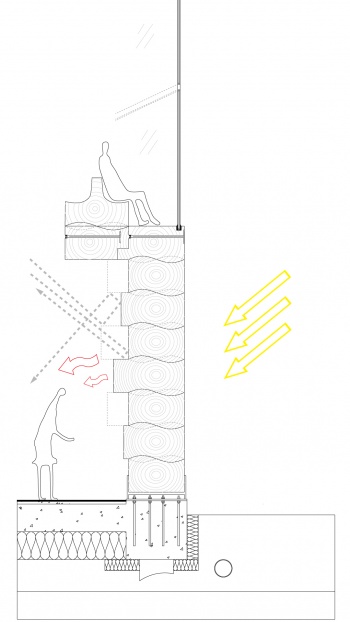

Thermal mass & Acoustics

The massive wood structure is exposed directly to the sun storying the heat using thermal mass to heat the building. The wood is therefore not insulated.

The irregular shifting of the blocks create cavities of different size and shape which scatters sounds creating a pleasant acoustical environment indoors.

Wall - Slan connection: The wooden pillar is resting an insulated concrete slab.

FABRICATION

Two robotic fabrication methods are used to give the massive wooden blocks their unique shape.

The first method is wire cutting, where a diamond wire suspended in a frame which is mounted on the 6 axis robot is used to cut the wooden blocks into geometries based ruled surfaces.

Similar method has been implemented for cutting stone and foam using hot wire instead of diamond wire. An example of this fabrication method is the Hyperbody 1:1 prototypes. Regardless of material the method is an effeicent way of producing unique elements that are based on ruled geometry.

The second on is milling using a bid mounted on the robot arm. The bid is designed in such a ways that it can remove material regardless of the the robot arms motion.

ICD/ITKE Research Pavilion 2011 designed and fabricated at Stuttgart Univeristy is an example of this fabrication method.