project19:Performance

Contents |

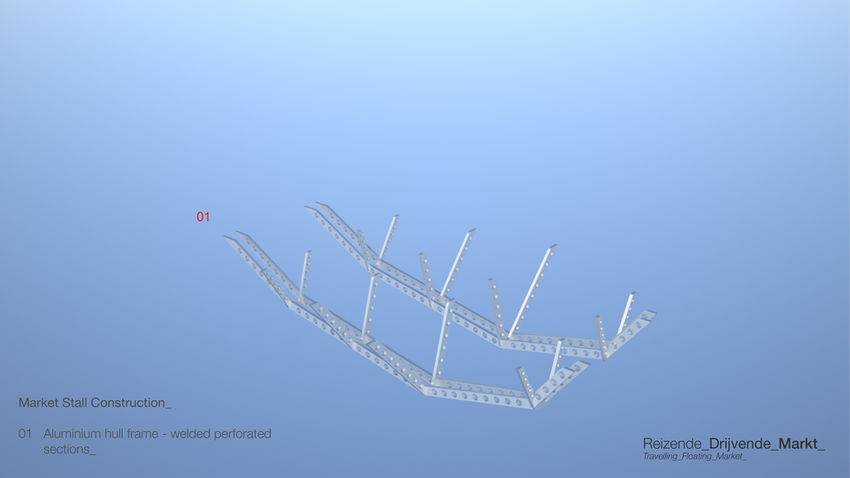

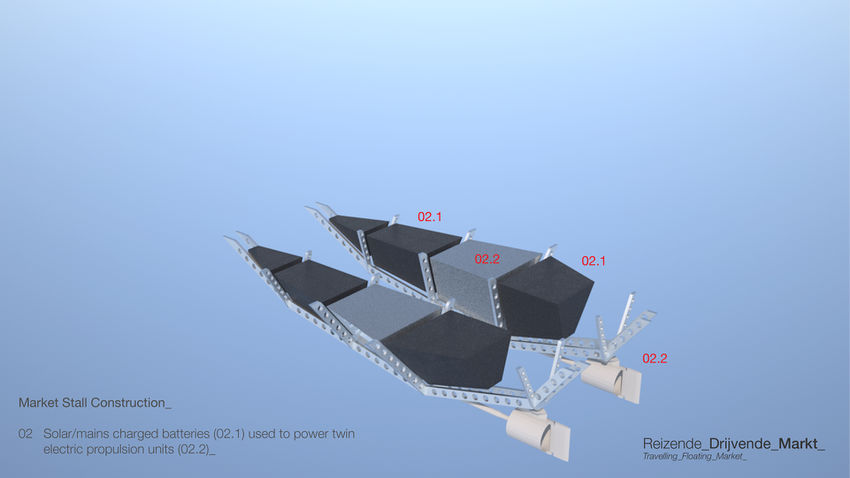

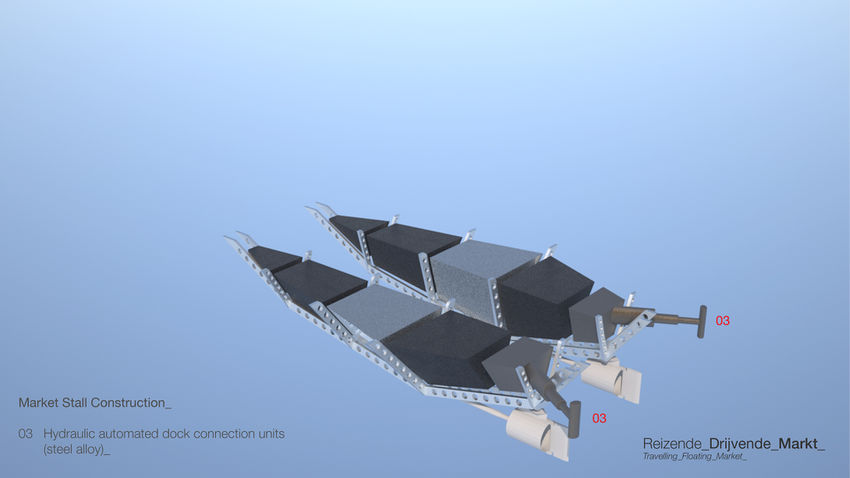

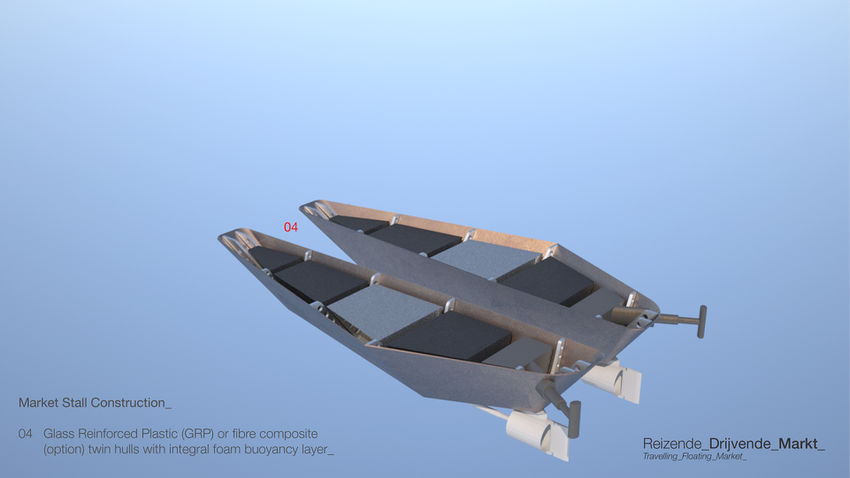

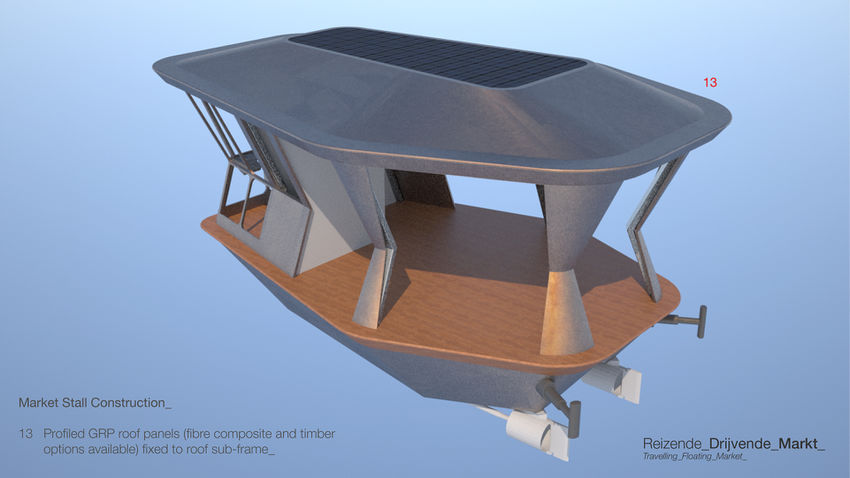

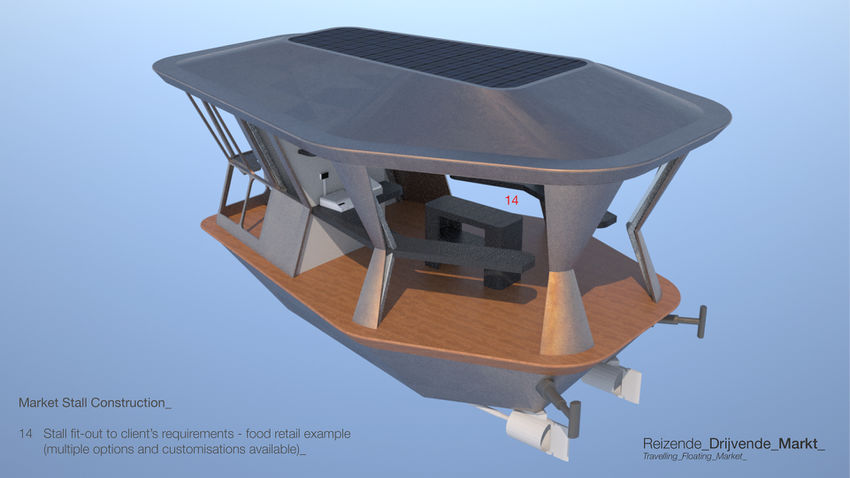

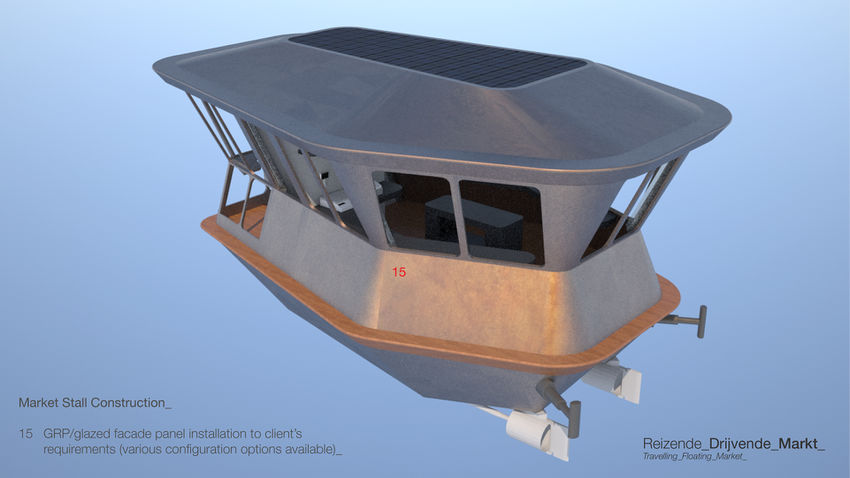

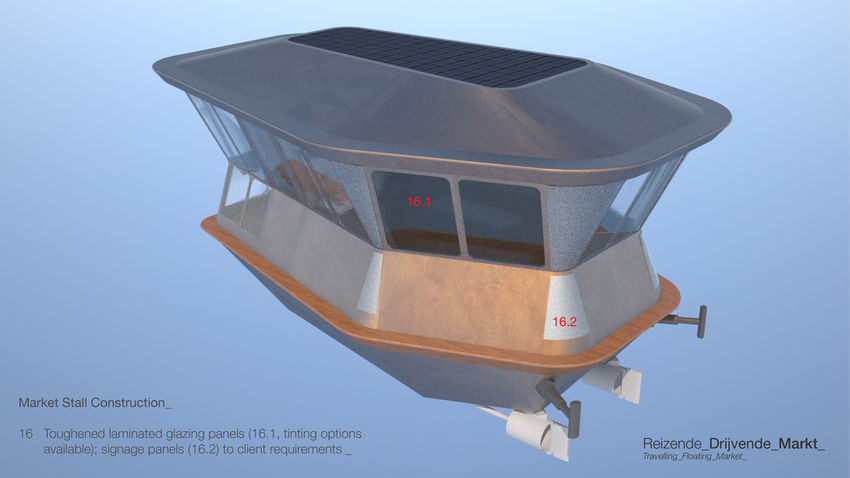

Market Stalls

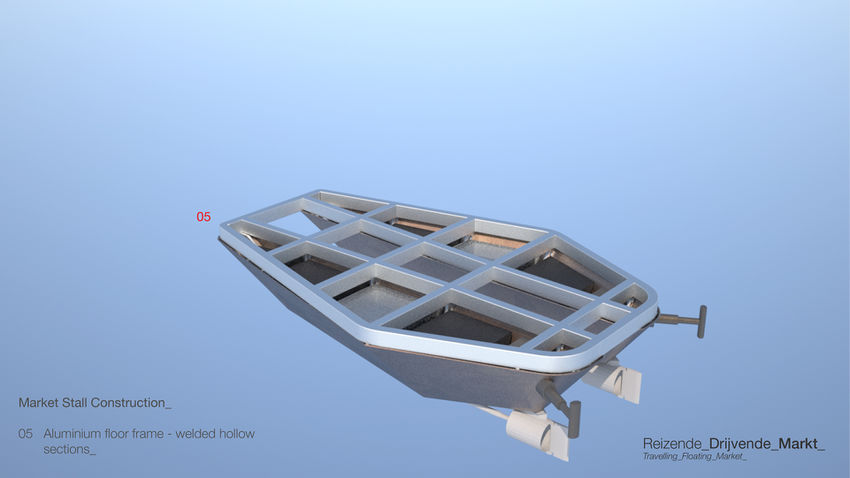

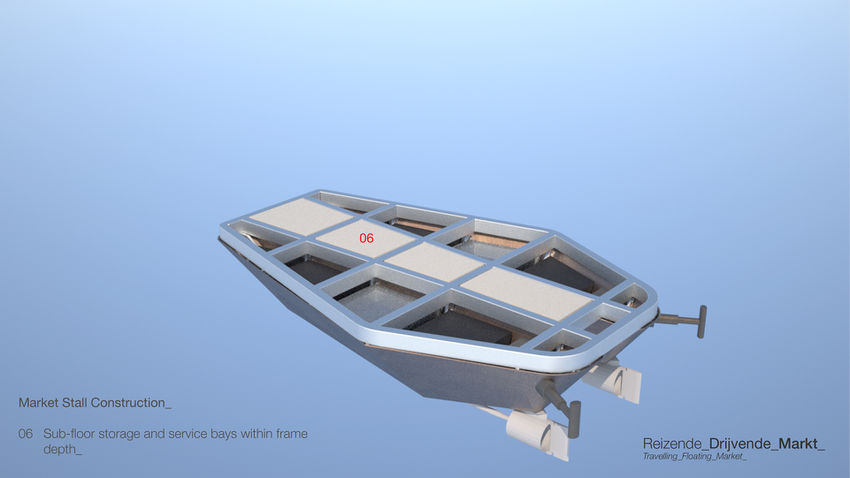

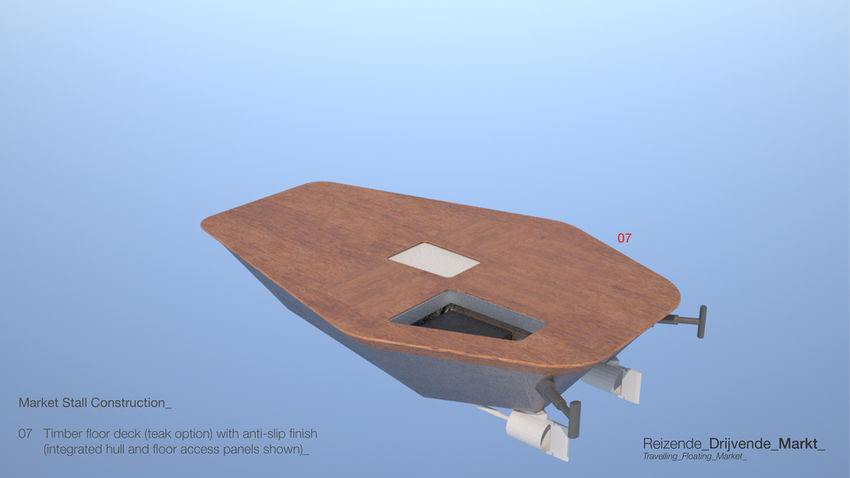

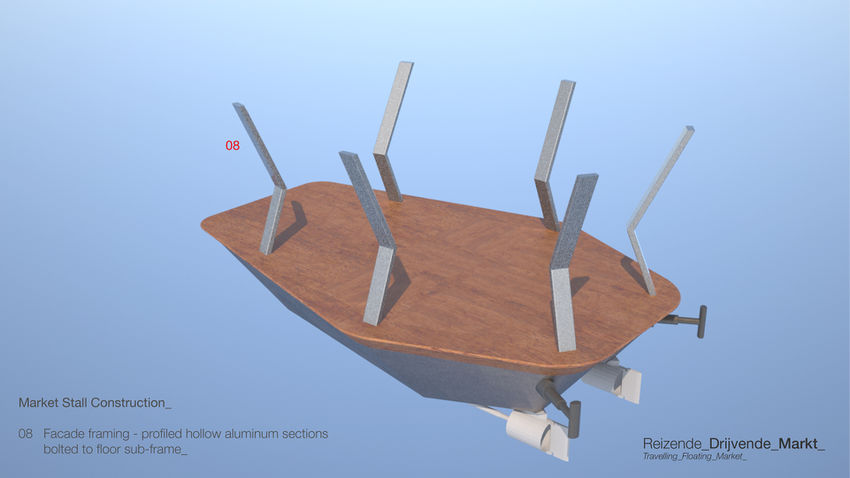

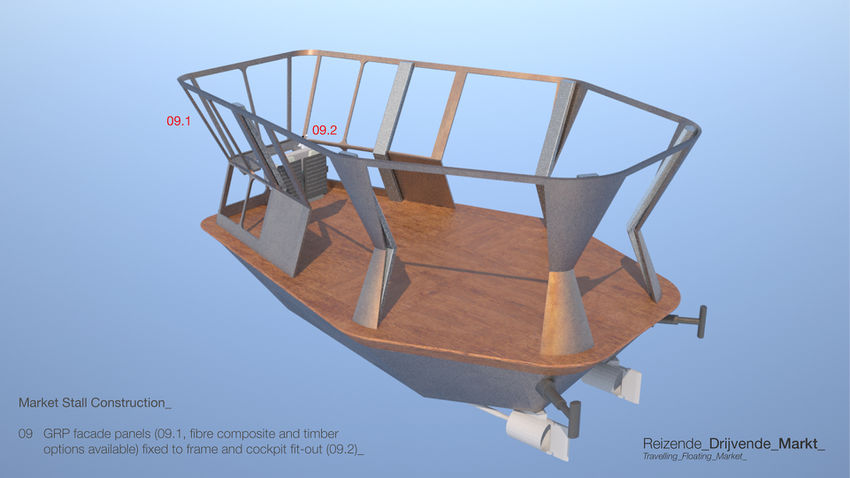

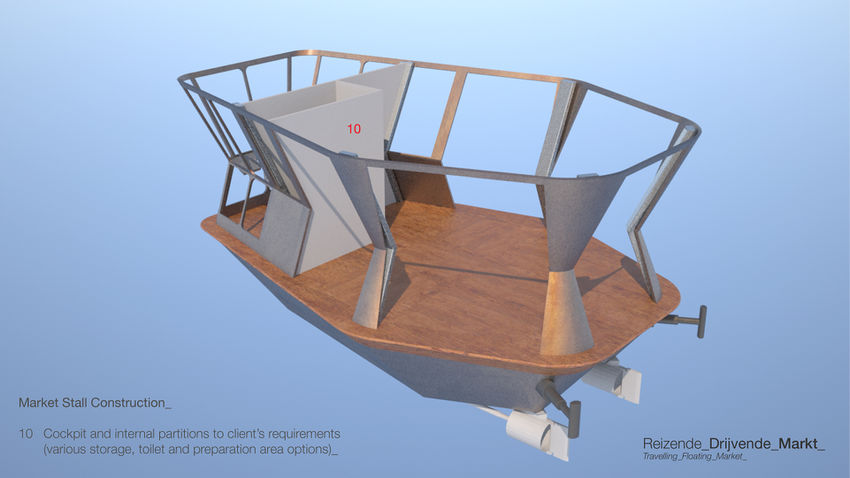

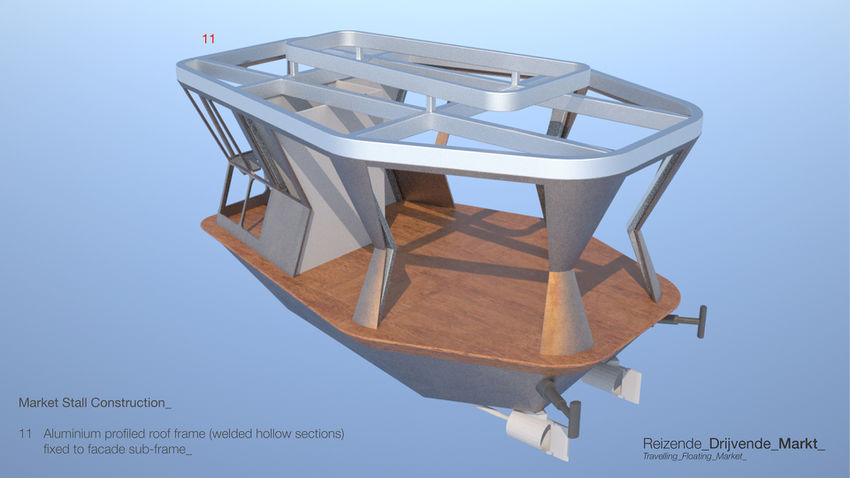

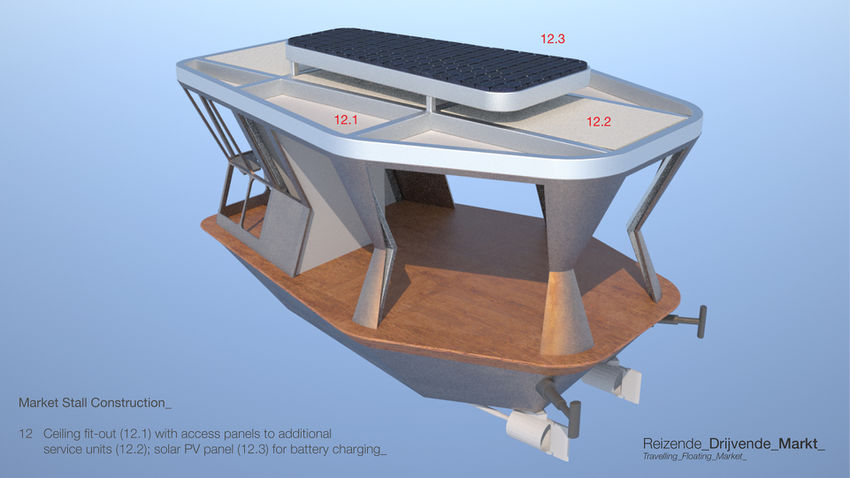

Construction Sequence (slideshow)

Promenades

01 - Rotating Access Bridges (slideshow)

To enable movement through the market by stalls and other boats, there are four rotating bridges located on key promenades (see plans) - here a recently refurbished market stall departs the dock adjacent to the Innovation Dock building.

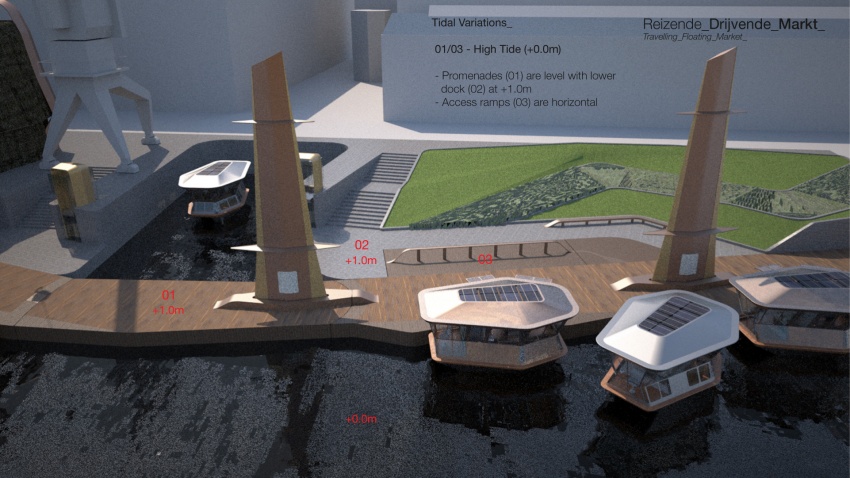

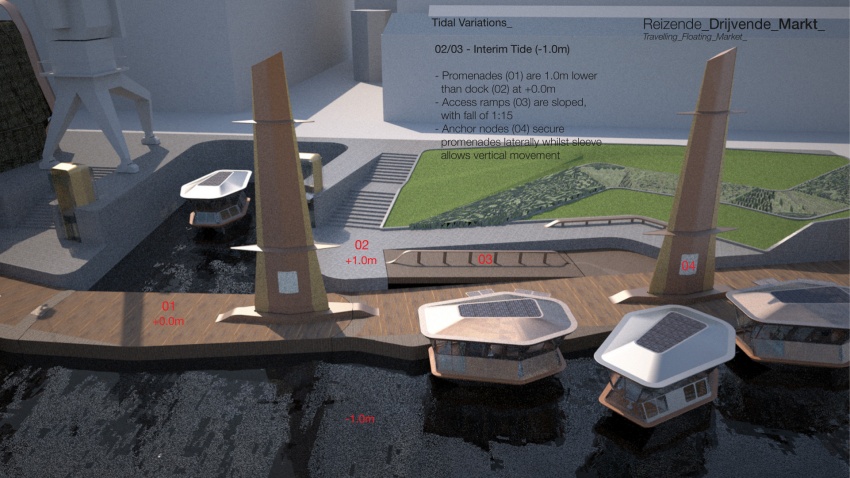

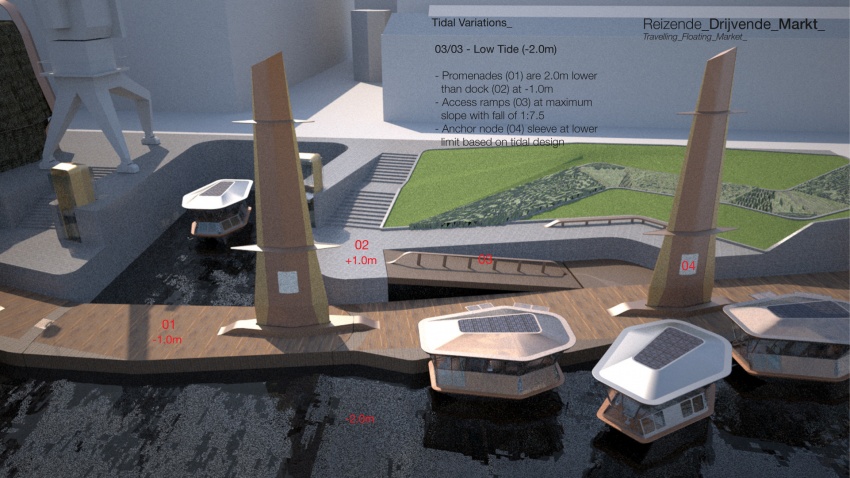

02 - Tidal Access Ramps (slideshow)

Structural Approaches

Framing

Hover over all images for accompanying text

Hub and Anchor Node Foundations

Promenade Buoyancy

Materials

01 Social Hubs

01 Steel panel with brushed alloy finish to profiled planters on roof (RAL 8008 olive brown)

02 Grass inlay to rooftop planters

03 Fair-faced reinforced concrete (RC) for slab and beams

04 Insulated timber facade panels with weathered larch profiled external batens

05 Steel perimeter frame with brushed alloy finish - cinema (RAL 8000 green brown)

06 Steel perimeter frame with brushed alloy finish - performance space (RAL 8003 clay brown)

07 Steel lift frame with brushed alloy finish (RAL1024 ochre yellow)

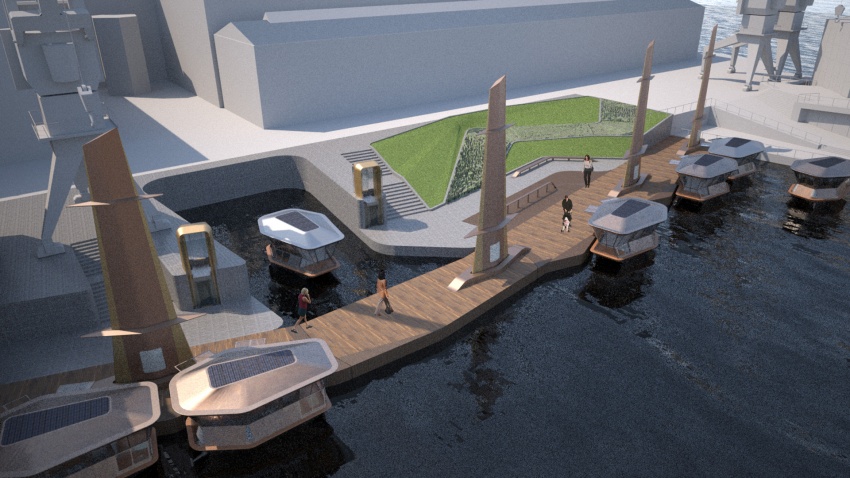

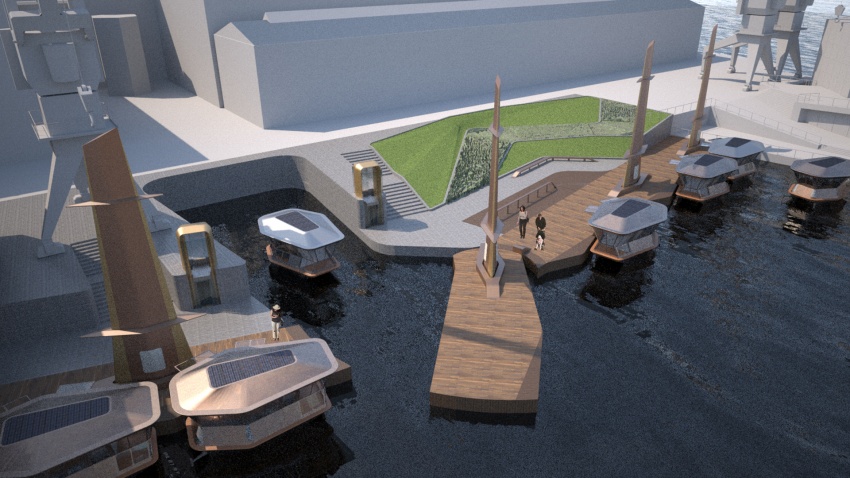

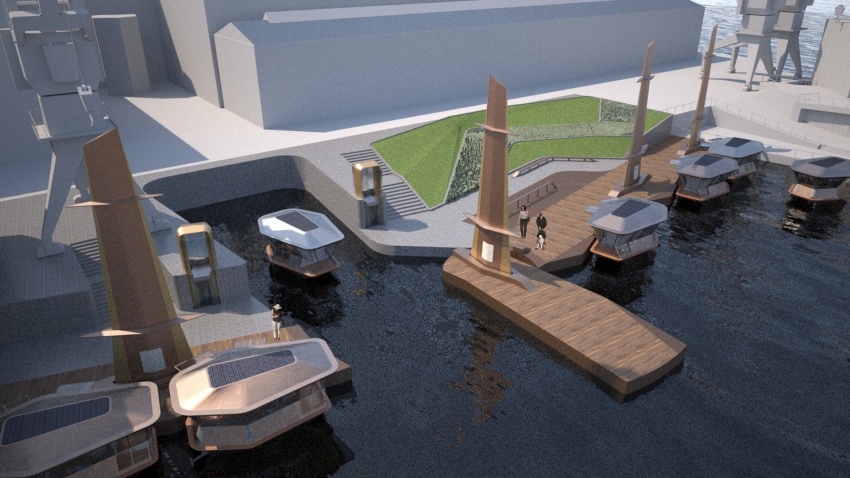

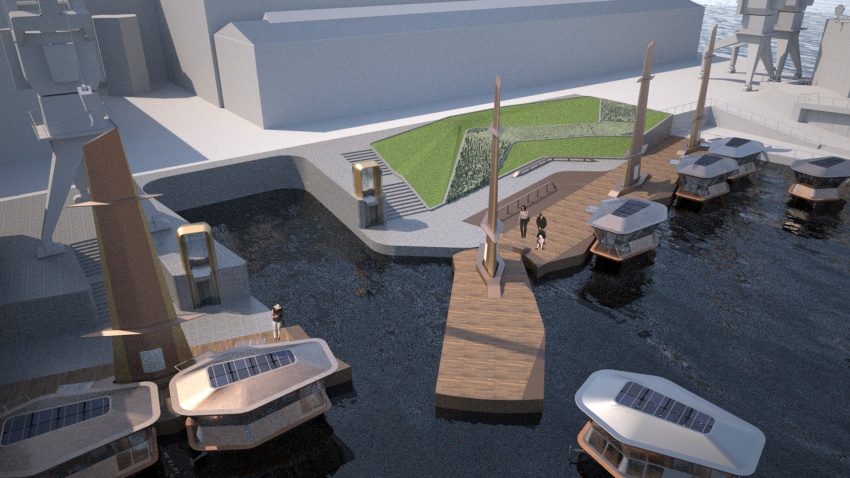

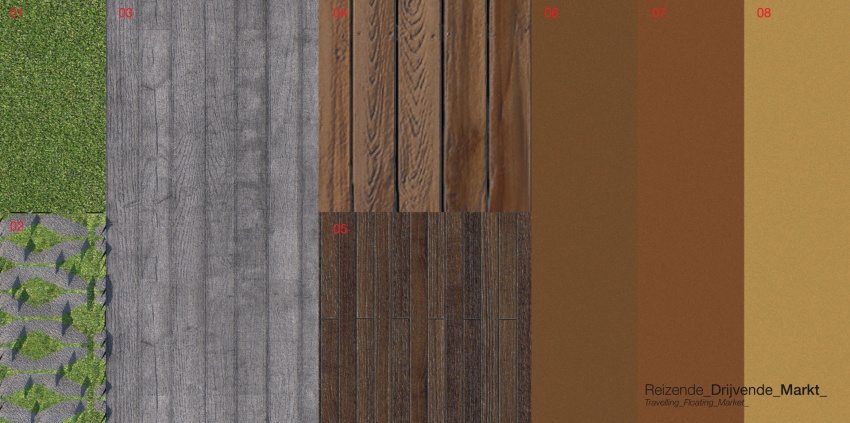

02 Dock and Promenades

01 Grass / vegetation to dockside green area

02 Grass-concrete paving to dockside ramp

03 Board-marked reinforced concrete (RC) to dock

04 Weathered teak decking with anti-slip finish to upper surface of promenades

05 Timber hull to promenades (dark stained with marine grade finish)

06 Steel panel with brushed alloy finish to central profiled seating and planters (RAL 8008 olive brown)

07 Steel profiled panels with brushed alloy finish to node anchor masts (RAL 8003 clay brown)

08 Steel panel flashing with brushed alloy finish to mast edges (RAL1024 ochre yellow)