project08:Performance

| (11 intermediate revisions by one user not shown) | |||

| Line 13: | Line 13: | ||

</div> | </div> | ||

| − | + | ==Performance== | |

| − | == | + | ===SEPAC structural system=== |

| − | + | ||

| − | + | During the sessions focused on building technology aspects I was advised to solve the internal structural system as an separate entity, that will bear the loads of the skin. Because of this an on-site cast concrete slab and column structure is proposed as a main load bearing element. This system transfers loads onto the seabed through the columns extending all way down. Part of the slab surface is also supported by the walls of concrete staircase and elevator shaft. In this case the loads are transferred further down by the underwater columns too. | |

| − | + | <div>[[File:Proj8 konstr building.gif|850px]]</div> | |

| + | GIF IMAGE PLEASE CLICK TO PLAY | ||

| − | + | ===SEPAC in detail=== | |

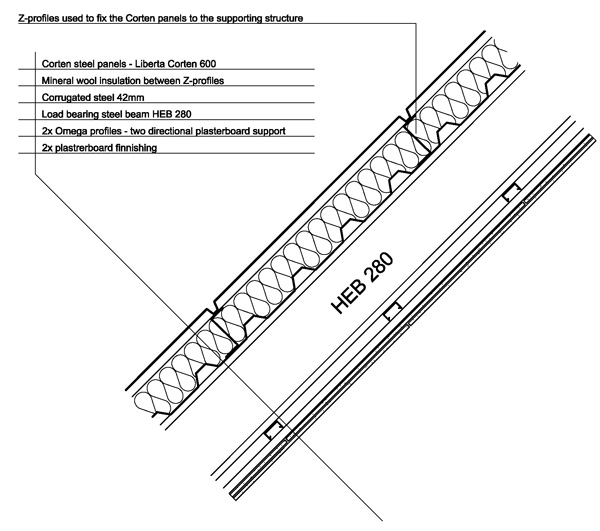

| − | + | The structure of roofs and the back walls of the main body is integrated. The load bearing frames are made of HEB 280 steel elements while the spaces between the frames are filled with the load bearing corrugated steel sheets, and supported additionally by HEB 100 beams, where the structure needs to cantilevers about 1000 mm to create a support for the skylights at the intersections. | |

| − | + | <div>[[File:Proj8 detail.jpg|600px]]</div> | |

| − | + | ===SEPAC louvers=== | |

| − | + | Besides the Corten finished sloping elements, SEPAC incorporates an ruled surface fully glazed facades with curvilinear louver system. The same system is applied to the facade of the office building, however in this case the base facade is rectilinear and the louvers are curvilinear. While the facade systems are proposed in variety of manufacturer offers, the curvilinear louvers systems needs to be fabricated by means of mass-customization. The full height facade has every louver element different, the same situation happens for the facade of the office block that touches the main SEPAC body. The other three are incorporating three series of 16 identical, curvilinear louvers. | |

| − | + | ===Sections of SEPAC=== | |

| − | + | Two sections were derived from the model and are presented below: | |

| + | |||

| + | <div>[[File:Proj8 sec (1).jpg|850px]]</div> | ||

| + | |||

| + | <div>[[File:Proj8 sec (2).jpg|850px]]</div> | ||

| + | |||

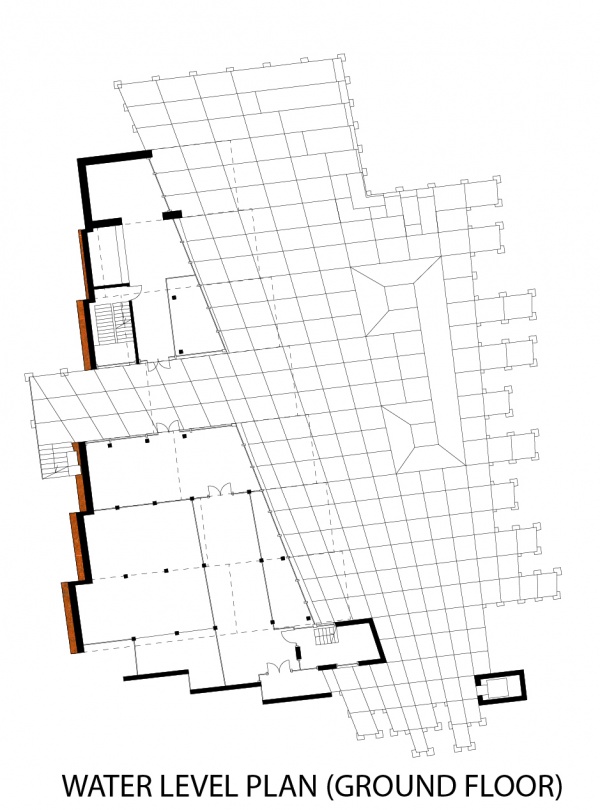

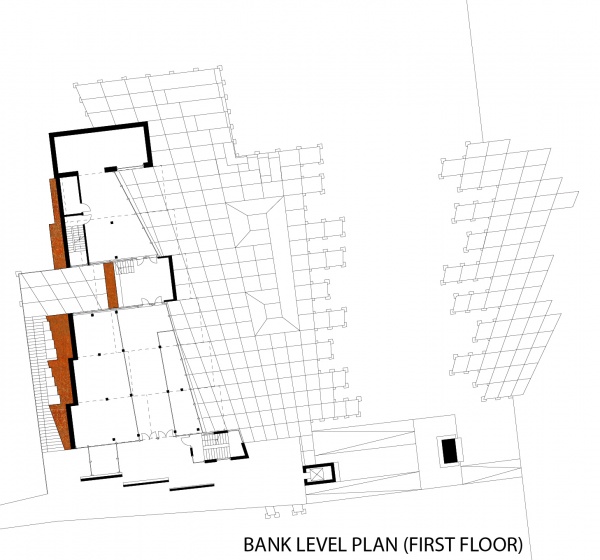

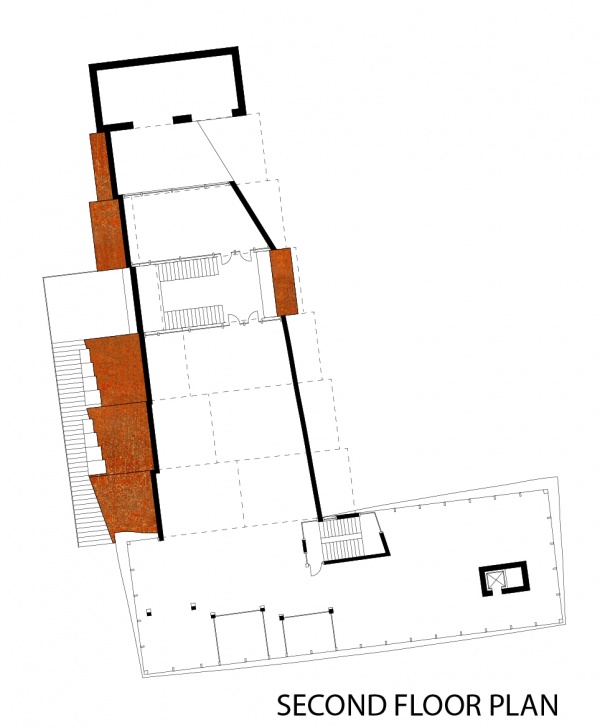

| + | ===Plans of SEPAC=== | ||

| + | |||

| + | Below I present plans of ground (water) level, first (ground) and second floor. Floor plan of the fourth level for the office building is analogous to the floor below, thus the drawing is not presented. | ||

| + | |||

| + | <div>[[File:Proj8 plan 0.jpg|600px]]</div> | ||

| + | |||

| + | <div>[[File:Proj8 plan 1.jpg|600px]]</div> | ||

| + | |||

| + | <div>[[File:Proj8 plan 2.jpg|600px]]</div> | ||

| + | |||

| + | </div> | ||

Latest revision as of 06:59, 22 January 2013

Performance

Contents |

[edit] Performance

[edit] SEPAC structural system

During the sessions focused on building technology aspects I was advised to solve the internal structural system as an separate entity, that will bear the loads of the skin. Because of this an on-site cast concrete slab and column structure is proposed as a main load bearing element. This system transfers loads onto the seabed through the columns extending all way down. Part of the slab surface is also supported by the walls of concrete staircase and elevator shaft. In this case the loads are transferred further down by the underwater columns too.

GIF IMAGE PLEASE CLICK TO PLAY

[edit] SEPAC in detail

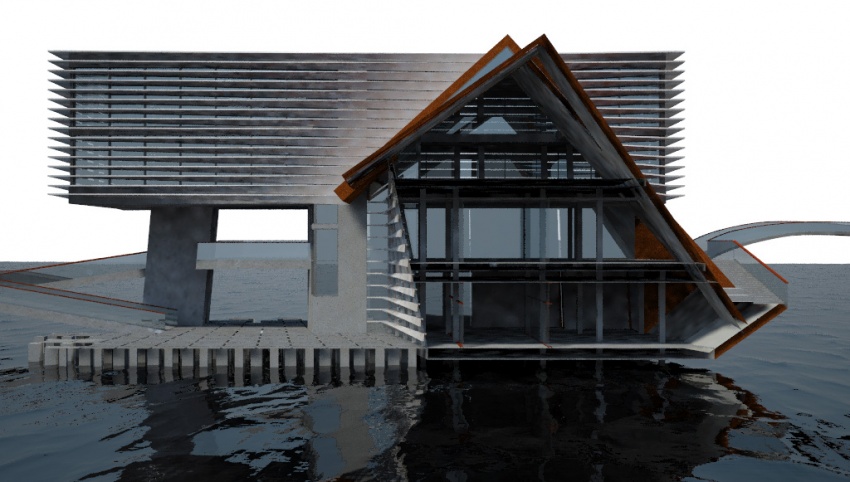

The structure of roofs and the back walls of the main body is integrated. The load bearing frames are made of HEB 280 steel elements while the spaces between the frames are filled with the load bearing corrugated steel sheets, and supported additionally by HEB 100 beams, where the structure needs to cantilevers about 1000 mm to create a support for the skylights at the intersections.

[edit] SEPAC louvers

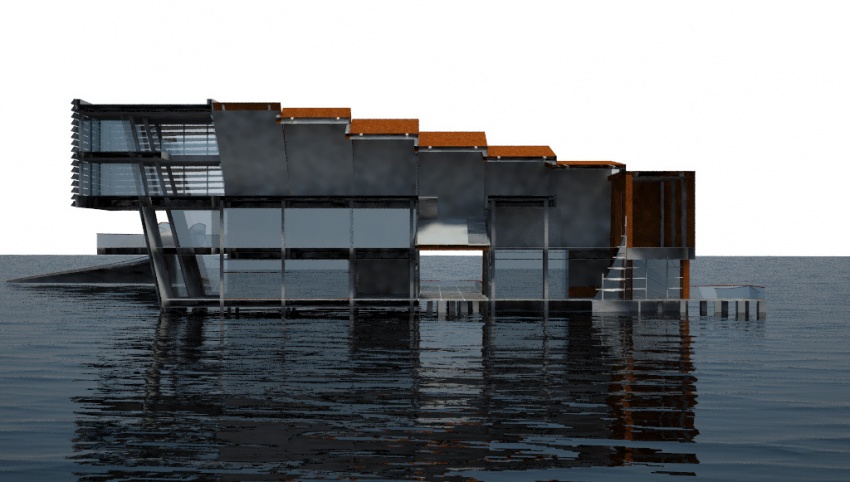

Besides the Corten finished sloping elements, SEPAC incorporates an ruled surface fully glazed facades with curvilinear louver system. The same system is applied to the facade of the office building, however in this case the base facade is rectilinear and the louvers are curvilinear. While the facade systems are proposed in variety of manufacturer offers, the curvilinear louvers systems needs to be fabricated by means of mass-customization. The full height facade has every louver element different, the same situation happens for the facade of the office block that touches the main SEPAC body. The other three are incorporating three series of 16 identical, curvilinear louvers.

[edit] Sections of SEPAC

Two sections were derived from the model and are presented below:

[edit] Plans of SEPAC

Below I present plans of ground (water) level, first (ground) and second floor. Floor plan of the fourth level for the office building is analogous to the floor below, thus the drawing is not presented.